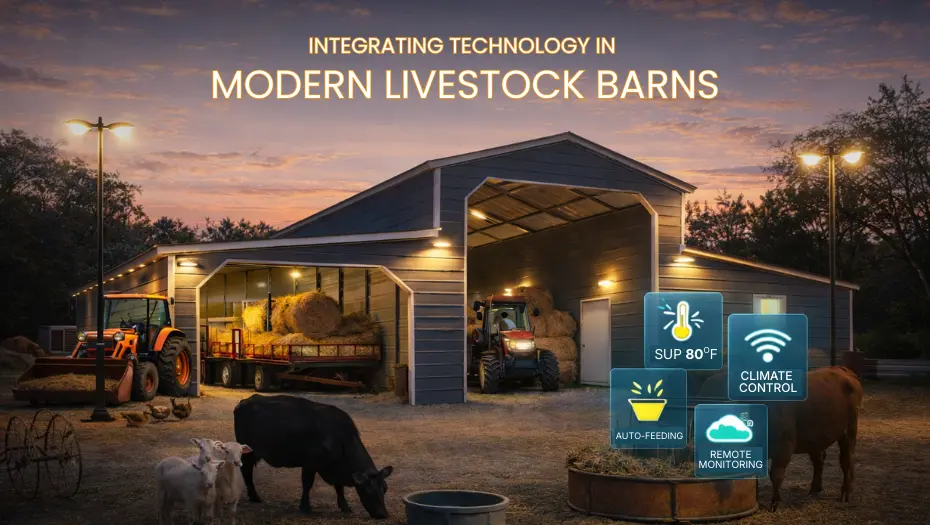

Integrating Technology in Modern Livestock Barns

Walk into a modern livestock barn today, and you might be surprised. You will not just see animals and feed, you will see screens, sensors, automated feeders, and climate systems quietly working in the background. Farmers now receive health alerts on their phones, monitor feeding patterns from dashboards, and control barn environments with a tap.

But smart technology needs a smart home. To run smoothly and reliably, these systems require strong, flexible, and future-ready buildings. That’s why more American farms are turning to steel livestock prefab barns that are built to support modern farming from the ground up.

What a “Modern Livestock Barn” Really Means Today

A modern livestock barn is not just a shelter for animals. It is a connected working environment that uses technology to monitor, manage, and protect livestock in real time. These barns are designed to improve animal comfort, reduce labor, and support smarter decision-making.

Across the U.S., farmers are adopting technology to meet rising production demands, labor shortages, and animal welfare standards. A well-designed metal farm building provides the strength, layout flexibility, and infrastructure needed to support these new systems.

The Technology Stack Inside a Smart Livestock Barn

A technology-enabled barn works like a system where every layer plays a role. From sensors and automation to software and analytics, each part supports daily operations and long-term planning.

Layer 1: Data Capture Through Sensors: Sensors are the foundation of a smart livestock barn. These devices collect real-time data on animal movement, body temperature, feeding behavior, rumination, and weight changes. Wearable collars, ear tags, and internal boluses allow farmers to track each animal individually. Sensors can be mounted securely on beams, walls, and ceilings without structural limitations. Steel framing enables proper cable routing, network coverage, and equipment placement, ensuring accurate data collection throughout the barn. This is why steel livestock barns for animal health are more suitable than other materials.

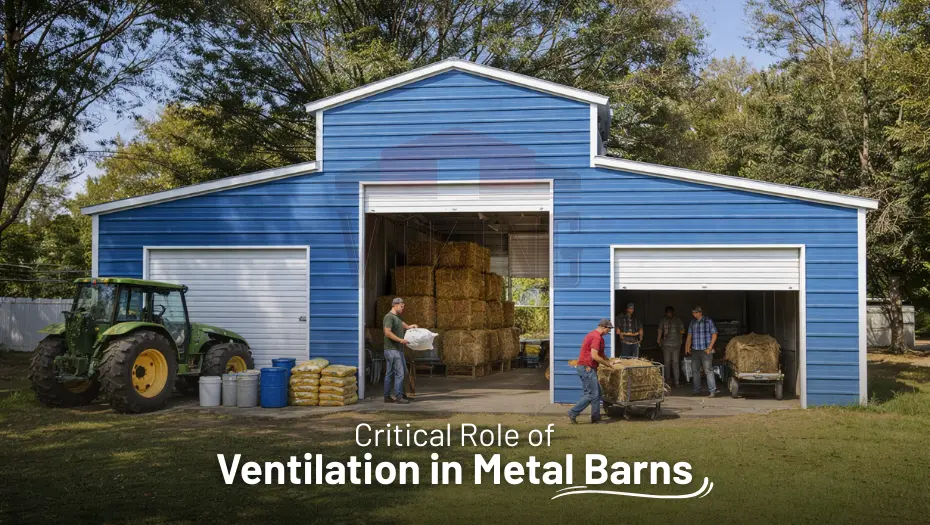

Layer 2: Environmental Monitoring and Control: The barn environment directly affects animal health and productivity. Smart climate systems monitor temperature, humidity, airflow, and air quality. When conditions change, automated systems adjust fans, curtains, heaters, or misting units automatically.

A commercial metal barn provides wide open spans and high ceilings that allow large ventilation systems to operate efficiently. Steel roofs and walls also support ducting, control panels, and climate sensors without weakening the structure.

Layer 3: Automation and Barn Equipment: Automation handles repetitive daily tasks that once required large labor crews. These systems include robotic milking, automated feeding lines, feed pushers, sorting gates, and smart water systems.

These machines are heavy and operate continuously, which requires a strong building foundation. A steel livestock barn offers the load-bearing capacity and durability needed to support automation safely for decades.

Layer 4: Software, Dashboards, and Analytics: All barn data flows into farm management software that turns information into action. Dashboards show animal health trends, feed consumption, milk output, and equipment performance.

Farmers receive instant alerts when something is wrong, whether it’s a sick animal, a water flow problem, or a temperature spike. Steel buildings allow secure installation of network hardware, control rooms, and server cabinets.

Technologies Farmers Are Actually Using Today

Modern livestock barns are already using a wide range of technologies that are transforming farm operations.

- Smart Health Monitoring Systems: Health monitoring tools track changes in animal behavior long before visible symptoms appear. Reduced movement can signal lameness. Lower feed intake can indicate illness. Temperature changes can point to infection. In a steel livestock barn, sensors remain stable and protected from damage. The clean structure reduces interference and improves accuracy, allowing farmers to respond quickly and prevent herd-wide problems.

- Precision Feeding and Nutrition Management: Smart feeding systems measure how much feed animals consume and automatically adjust rations. This prevents overfeeding, reduces waste, and ensures balanced nutrition for every animal. Metal structures support overhead feed delivery systems, automated pushers, and digital feed stations. The open layouts allow tractors and robots to move freely without obstruction.

- Robotic Milking and Dairy Technology: Robotic milking systems allow cows to be milked on their own schedule, improving comfort and productivity. These systems require strong floors, a stable power supply, network connectivity, and climate control. Large dairy operations rely on commercial steel barns because robots need space, ventilation, and structural strength. Steel buildings also make it easy to expand when herd size grows.

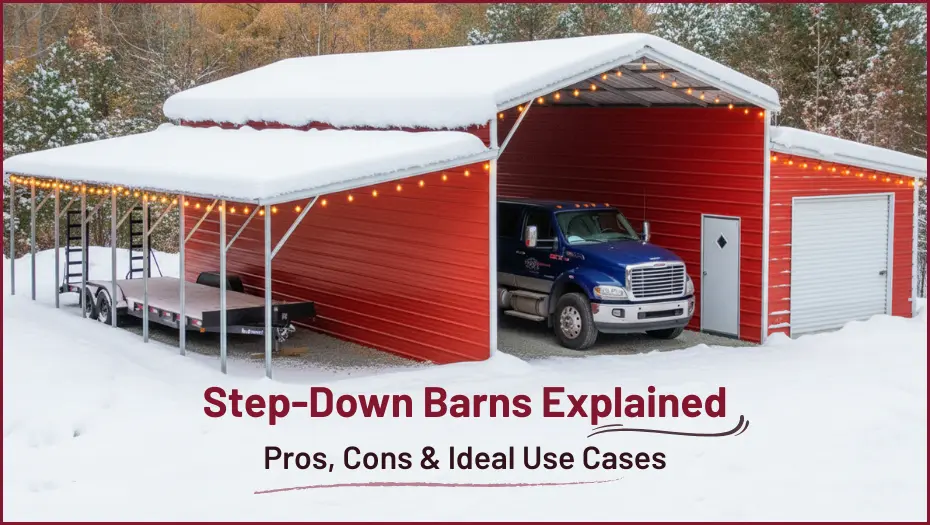

- Climate Control and Heat Stress Prevention: Heat stress reduces feed intake, fertility, and milk production. Smart barns use sensors to detect rising temperature and humidity and activate cooling systems automatically. A step-down barn design combined with steel framing improves natural airflow. When paired with smart fans and misting systems, it creates a cooler and healthier environment for livestock year-round.

- Security and Remote Monitoring: Modern barns use cameras, motion sensors, and access control systems to protect animals, feed, and equipment. Farmers can check live footage, receive alerts, and monitor barn activity from their phones. Many farms now build metal barns with living quarters, allowing farm managers to live on-site while staying connected to barn operations 24/7.

What Farms Gain from Smart Barn Technology

Technology delivers measurable benefits across every part of the operation. Here is the list of some benefits you get by integrating technology into your steel barn.

- Better Animal Welfare: Animals live in cleaner, cooler, and more stable environments. Early illness detection reduces suffering and improves recovery rates. Smart ventilation improves air quality and reduces respiratory problems. A steel livestock barn for animal health ensures that every system operates reliably and safely.

- Improved Labor Efficiency: Automation reduces manual workload. One worker can manage more animals with less physical strain. Tasks like feeding, sorting, and milking run automatically. Steel barns are designed for machinery movement and equipment access, allowing smooth daily operations.

- Smarter Farm Decisions: Data replaces guesswork. Farmers make informed decisions based on trends instead of assumptions. This improves breeding programs, feed efficiency, and long-term planning.

- Stronger Sustainability Practices: Smart water systems reduce waste. Climate control improves energy efficiency. Manure tracking reduces runoff risks. Metal barns support these systems and help farms meet environmental standards. They are suitable to shape the future of farming.

What It Costs to Build a Smart Livestock Barn

Technology investment depends on farm size and automation level. Entry-level systems include basic sensors and monitoring dashboards. Mid-level systems add climate control and automated feeding. Advanced systems include robotics and full integration. Prefab buildings reduce installation costs because equipment mounts easily to steel frames and requires fewer modifications.

How to Upgrade Your Barn Without Disruption

Modernizing a barn should be done in stages. So, here are some stages for you to follow.

- Start With One Problem: Focus on one challenge, such as heat stress, labor shortages, or calf monitoring. Install technology that solves that issue first.

- Build Strong Connectivity: A smart barn needs reliable internet and network coverage. Steel structures support antennas, routers, and cable systems easily.

- Pilot Before Expanding: Test systems for 60–90 days. Measure results. Expand only what delivers real value.

- Train Your Team: Technology works only when people trust it. Train staff to respond to alerts and follow digital workflows.

Common Mistakes to Avoid

Many farms fail with technology because they buy systems without clear goals in mind. Others install disconnected tools that don’t communicate with each other. Skipping maintenance, ignoring power backups, and undertraining staff also cause problems. The most successful farms build their smart barns step by step.

The next generation of barns will use AI for health prediction, computer vision for body condition scoring, and fully connected farm ecosystems. From seneca barns to large commercial steel barns, today’s metal farm buildings are shaping what’s possible.

Secure Your Modern Barn With the Experienced Dealer

Building a smart livestock barn is not just about adding technology; it’s about choosing the right partner to bring everything together. That’s where Viking Barns stands out. As a trusted metal building dealer, it offers custom-designed steel barns, expert guidance, and end-to-end support from planning to installation.

Their dedicated team helps farmers choose the right layout, structure, and features to support automation, animal comfort, and future expansion. When you work with Viking Barns’s team, you not just buy a building, you invest in a long-term solution built for modern farming.

Alabama AL

Alabama AL

American Steel Carports Inc.

American Steel Carports Inc.