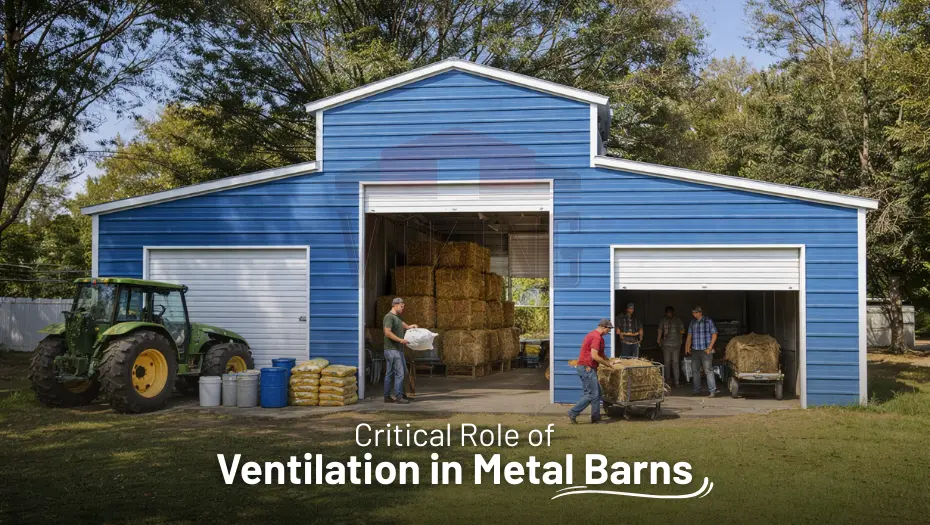

The Critical Role of Ventilation in Metal Barns

When you are building a steel barn, one thing that often gets overlooked despite being crucial is ventilation. Proper airflow is vital not only for people living inside the building but also for things stored. It’s also crucial for energy savings and long-term performance as well. If you want to know the role of ventilation deeply, this write-up is for you.

We have explained thoroughly why ventilation matters that much, how it works in metal structures, and what the USA is facing in terms of ventilation issues today. So, do you want to know everything about ventilation? Scroll down quickly.

Why Ventilation Matters in Metal Barns

What is ventilation? It’s simply the exchange of indoor air with outdoor fresh air so that you can maintain good air quality, manage temperature and humidity, and prevent harmful build-up of gases, moisture, or heat in your steel structure.

In a steel livestock barn environment, poor ventilation can lead to:

- Moisture and condensation build-up, which can cause structural damage, rust, mold, or rot in attachments. Moisture damage is a direct result of poor ventilation.

- Heat stress for animals or humans inside the barn reduces productivity, health, and comfort. For example, in dairy barns, heat/humidity reduces feed intake, milk production, and increases disease risk.

- Build-up of ammonia, gases, dust, or stale air in livestock facilities affects air quality and livestock welfare.

- If your barn is cold, damp, or overheating, you will often spend more on heating/ventilation or repair later. With metal buildings, saving more is easy if ventilation is done right.

- For a metal barn building and custom barn structure, metal roofs, wall panels, and insulation all work best when moisture, temperature fluctuations, and airflow are managed.

How Ventilation Principles Apply to Steel Barns

Let’s dig into the “How” of ventilation in steel barns and what you should consider when designing.

Here are some main approaches:

- Natural (passive) ventilation: Using wind, temperature differences, and openings (vents, louvers, ridge vents) to drive airflow without mechanical power. For example, in livestock housing, many US extension services recommend continuous ridge vents and eave openings to allow air exchange.

- Mechanical ventilation: Using fans, exhaust systems, ducts, etc, to force air exchange and circulation. This gives more control but uses more energy and requires more maintenance. For example, in horse barns, “mechanically-ventilated barns are designed for year-round conditions” with fans and inlets.

- Hybrid systems: You can combine passive and mechanical approaches, which is often ideal in a barn that has both livestock and storage, or that must adapt to hot summers and cold winters. For example, in dairy barns, natural ventilation is used in cold weather and mechanical ventilation during hot weather.

Key Components for a Metal Barn:

When you are constructing or designing a custom steel building, here are the features you should focus on:

- Ridge vents: These let hot air rise and escape from the peak of the roof. In metal barns, this is particularly vital because metal roof surfaces can heat up quickly.

- Eave vents/overhang vents: Low sidewall vents allow cooler outside air to come in and provide intake. Then, ridge vents or other outlets let warm/stale air go out. This creates the desired flow.

- Sidewall louvers/windows/doors: Especially in large steel barns, sidewall openings help with cross-ventilation (side-to-side) or tunnel ventilation (end-to-end). In livestock barns, that matters for air distribution.

- Exhaust fans/circulation fans: Especially when natural ventilation will not suffice due to climate, density, insulation, or occupancy, you will need mechanical fans to maintain adequate exchange. This is common for prefab structures used for livestock or human-occupied space.

- Insulation and vapor/moisture control: In steel barns, insulation and moisture management go hand-in-hand with ventilation. Without moisture control, you get condensation on the underside of metal panels, which can drip, corrode, and damage finishes.

What You Should Consider When Planning Ventilation for a Metal Barn:

- Account for seasonality: In winter, you might need fewer exchanges but still need to remove moisture; in summer, you need higher air changes to remove heat/humidity. For example, some dairy barns need around 4 air changes per hour in winter, maybe every 15 minutes, and 40-60 in summer.

- Consider occupancy and usage: If your steel barn building houses many animals, stores hay, or is used for people/workshops, ventilation needs are higher. It is because the type and density of use affect the rate.

- Structural impacts: Pre-engineered spaces conduct heat differently. Metal roofs and walls heat up and cool down quickly. This is why, without proper ventilation, you can get heat soak or rapid condensation.

- Durability & maintenance: Ventilation fans, louvers, and vents need maintenance; otherwise, the system will degrade. Often dirty fans reduce airflow by 10-40%. So cleaning is also crucial for proper ventilation.

Best Practices for Designing Ventilation in Your Steel Barn

Here are some practical tips you can use when designing or building a metal barn for better ventilation.

Start early in design: Ventilation should be part of the design process for your custom barn structure. Don’t treat it as an afterthought. Place ridge vents, eave vents, louvers, windows/doors, and fans in planning.

- Use appropriate openings: For passive systems, ensure the ridge vent area and eave vent area are sized correctly relative to building width and layout.

- Consider orientation & wind: Where possible, orient your barn to leverage prevailing winds for intake/outlet. Place doors and windows accordingly for cross or tunnel ventilation.

- Choose durable materials: In steel barns, you will have exposure to temperature swings, moisture, and animal environments. This is why you should choose fans, louvers, and vents that resist corrosion, as they are easy to maintain.

- Insulate wisely: Even though metal barns might be more “open,” proper insulation and vapor control help reduce condensation and heat load, which allows ventilation systems to work more efficiently. The horse barn guidance suggests roof insulation R-value and vapor barriers.

- Design for maintenance: Make sure fans are accessible, vents are cleanable, and louvers are openable. Often, dirty fans reduce performance significantly. So, it’s crucial to keep them clean.

- Tailor to usage: If you are storing equipment, doing workshops, housing animals, or people, your ventilation needs change. For steel livestock barns, include ammonia control, higher airflow, and possibly zoned ventilation.

- Monitor and adjust: After building, monitor temperature, humidity, condensation, and air movement. If you notice damp spots, drips, mold, or stale air, you may need additional vents or mechanical help.

- Plan for future-proofing: If you might later use the steel livestock barn for something else, e.g., human workspace, living quarters, or expand occupancy, design your ventilation system to handle increased loads or add a mechanical supplement later.

Example: Applying All This to Your Metal Barn Building Project

Let’s imagine you are building a 60-ft × 120-ft steel barn for both livestock and storage in a U.S. midwestern climate where summers are hot and humid, and winters are cold. Here’s how you might apply the factors discussed above.

- Design phase: Choose a layout that gives you a good span for livestock stalls on one side, storage on the other. Decide on a ridge vent along the entire roof peak, plus continuous eave vents along each long side.

- Mechanical system: Install sidewall exhaust fans plus circulation fans inside. Let’s assume that in the hottest months, you will hit target air changes of 40-60 per hour on the livestock side.

- Materials & insulation: Use metal panels with good coating, choose fans rated for damp/dirty farm conditions, and install insulation on the roof and walls with a vapor barrier so you can prevent condensation on the metal surfaces.

- Monitoring & maintenance plan: On a monthly basis, check fans, belts, vents, and humidity levels, look for dripping surfaces, rust, and mold. Moreover, clean fans before summer when ventilation needs spike.

- Budget & savings: Because you picked metal structures for sustainable farming, you can highlight that, though the initial cost is a bit higher than a minimal structure, you save more with metal buildings. It is because of steel’s durability and better environmental control.

- Usage flexibility: If later you decide to convert the storage part into living quarters or workshop, you already have mechanical ventilation, plenty of inlets/outlets, durable structure. Everything future-proofs your investment.

Want a Better Airflow in Your New Steel Barn?

No doubt, airflow is essential for any metal building, especially barns. But proper ventilation highly depends on the workers who install the structure. If you want to put the best foot forward with accurate ventilation, consider working with a trusted provider like Viking Barns. We guide you through choosing the right custom barn structure. We help you choose the right ventilation features and select the best insulation for your building. Moreover, our team simplifies the process and provides you with a barn that lasts for years.

Alabama AL

Alabama AL

American Steel Carports Inc.

American Steel Carports Inc.