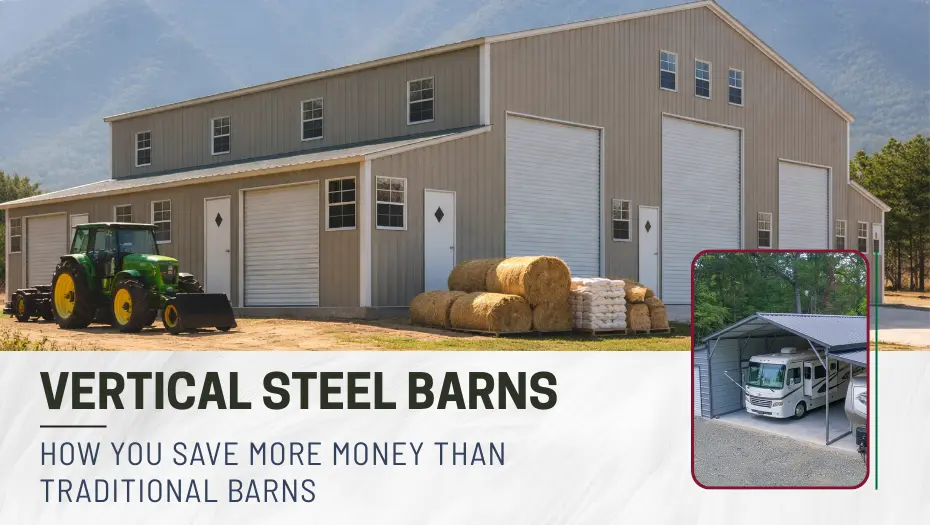

How Vertical Steel Barns Save You More Money Than Traditional Barns

Do your eyes stick on the price tag when you want to buy a barn? However, it’s the cost you see now, but what about the cost you have to pay over time after purchasing a barn? If you really want to save on your farm building, try to analyze what happens after it is installed. If you have to face a lot of repairs, upkeep, and replacement issues, the cost would pile up over time. If you have ever used traditional barns, you must have noticed this problem in them.

A vertical steel barn outperforms a traditional barn due to its impressive features. A vertical roof barn is unlike other types of roof designs; it is designed to withstand harsh weather, remain strong, and prove to be the best investment for its owner. It is engineered to handle snow, wind, water, and even thermal expansion more effectively.

Every feature helps you save more on this steel building. Want to know more about this impressive engineering marvel? Scroll down to the details.

What Makes a Vertical Roof Different?

When you look at a vertical roof steel barn, you think there is nothing special about it. The panel orientation sets it apart and makes it a special structure for people in the agribusiness and others.

- Vertical Barns: Panels run from the peak of the roof down to the eaves. This design guides rainwater, snow, and debris to slide off the roof naturally, so the roof doesn’t have to bear the load.

- Horizontal/boxed-eave Barns: Panels of these types of structures run side-to-side, horizontally. This type of layout allows water or snow to collect on the roof because it gets stuck in the panels.

This difference in direction may look small, but it has a big impact on performance. In fact, building buyers often search for “How does vertical roof panel orientation affect snow shedding capacity?” The answer is simple: vertical panels let gravity do the work, reducing buildup and minimizing structural strain.

Comparing Vertical Roofs to Traditional Barn

You may have been using traditional wooden barns for a long time, but they struggle to meet the needs of modern farmers and businesses, and help them save more over time. Let’s compare and understand why.

|

Features |

Vertical Roof Barn |

Traditional Barn |

|

Roof Panel Direction |

Vertical |

Flat roof |

|

Weather Resistance |

Handles snow, rain |

Struggles with heavy snow and storms |

|

Maintenance Needs |

Very low |

High |

|

Lifespan |

40–60 years with coatings |

15–25 years |

|

Cost Over Time |

Lower due to fewer repairs |

Higher due to constant maintenance |

|

Structural Strength |

Strong steel frame |

Vulnerable to rot, termites, and sagging |

What Makes Vertical Roofs Robust So They Can Save More

As mentioned above, a vertical metal barn’s roof panels run top to bottom, which makes the structure robust. However, this is not the only reason that makes the structure strong and cost-effective; many more technical aspects contribute to its strength and efficiency.

1. Panel Geometry & Seam Design: Vertical panels use ribbed profiles with raised seams. This is why the design is widely used for constructing a raised center barn. The rib height (often ¾” to 1½”) channels water away quickly. Some structures use standing seams, where panels interlock tightly, creating a watertight seal. This reduces leaks, even during driving rainstorms. Traditional barns don’t have these vertical channels, so water tends to sit longer, which mostly leads to rust and rot in the traditional structure. With a vertical barn, you don’t have to face these problems because it requires fewer leak repairs and offers longer roof life.

2. Fastener Strategy & Uplift Resistance: Many metal structure buyers with good technical knowledge ask: What fastener system reduces wind uplift on vertical metal roofs?” Well, vertical barns often use engineered fastener spacing or even concealed clips. These clips hold panels firmly but still allow thermal movement. That prevents screws from backing out; you have seen it’s a common issue in horizontal roofs. Engineers design these systems to resist wind uplift forces, sometimes rated to withstand gusts over 120 mph, depending on local codes. As a result, you can save on lower storm damage bills and fewer calls to reseal screws.

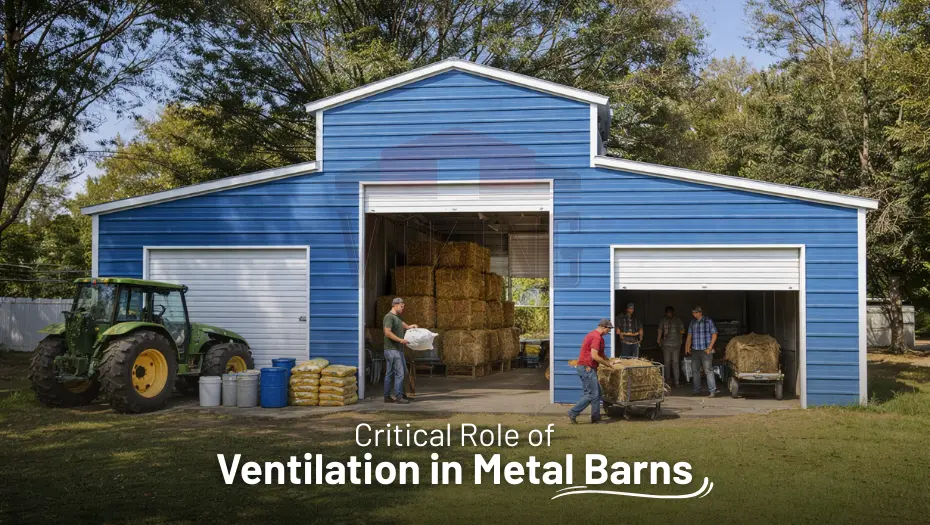

3. Purlins, Girts & Load Path Design: Other barns often nail panels directly to rafters. Vertical barns, however, use purlins (metal framing laid horizontally across rafters). These purlins distribute weight evenly, creating a continuous load path from the roof to the foundation. That means heavy snow or wind loads don’t overload one spot. Instead, the stress spreads across the structure. Resultant, there are fewer chances of structural failure, fewer emergency repairs, and lower insurance claims. If you house animals inside, they will remain safe, regardless of how harsh the weather is outside the livestock metal barn.

4. Underlayment & Condensation Control: Another overlooked cost is condensation damage. Moisture trapped under a roof can corrode panels or ruin stored items. Vertical roofs often pair with vapor barriers, breathable underlays, or insulated liners during construction. These elements control condensation and extend the roof’s life. Traditional and horizontal barns do not employ this type of engineering, which is why they are more prone to water trapping and require more maintenance over time. Meanwhile, vertical metal building requires fewer corrosion repairs and less damage to stored equipment or livestock areas.

5. Roof Slope & Snow/Ice Handling: If you live in snowy regions, you have likely wondered: “How does vertical roof slope affect roof lifespan?” These roofs typically feature a steeper pitch (3:12 or greater). This slope lets snow and ice slide off naturally. Since most traditional barns are made of timber, they face issues with quickly sliding off the water. Often, a rotting issue occurs because some snow and water particles remain on the roof for extended periods. You have to spend on expensive snow guards. But with a vertical barn structure, you don’t have to invest in expensive snow removal labor and roof collapse repairs.

6. Coatings, Galvanization & Corrosion Control: Traditional barns do not typically come with coatings and galvanization due to their material texture. Steel’s texture and nature allow easy coatings and galvanization for the entire structure. It controls corrosion issues and saves the structure from deterioration. Moreover, the slope helps rain wash dirt and chemicals away, preventing corrosion. States with extreme weather conditions need this type of structure to lower repainting and replacement costs over time.

Installation Best Practices for Vertical Steel Barn

You can also save money by following the best practices for installing a vertical roof structure. Proper anchoring keeps the barn steady during storms, so you don’t need to spend on repairs after every high wind. Correct panel alignment ensures water and snow slide off smoothly, preventing leaks and rust that would cost you later. Moreover, adding sound insulation during installation reduces energy bills from day one. Even small details, such as sealing edges and using the right fasteners, prevent minor issues from becoming major expenses. In short, smart installation today means fewer repairs, lower bills, and decades of worry-free use tomorrow.

Insurance, Warranties & Resale Advantages

When a structure is so strong, dealers also offer better warranties. And insurance companies get ready to provide better claims for the buildings. This is why well-engineered vertical roofs often get lower insurance rates. Warranties may cover 40+ years on paint and structure by the company you partner with. Moreover, if you want to sale the barn in the future, you can get better resale value because buyers view vertical barns as a higher value structure.

Want a Smarter Long-Term Choice?

Vertical roof metal barns can be engineered to save you money if experienced installers are involved in their construction. Yes, you read it right. You need to partner with a top metal building dealer, such as Viking Barns. It offers a wide range of steel barn buildings made of high-quality components. So, you can easily secure a smart long-term choice with us. Here is what you get with us.

- Customized steel structures

- American-made steel components

- Flexible financing

- 20-year warranty

You can connect to our experts at any time using [Phone Number]. Discuss with them what exactly you want in a structure, and clear all your doubts before you hit the buy button.

Alabama AL

Alabama AL

American Steel Carports Inc.

American Steel Carports Inc.