Why Metal Building Prices Are Going Up in 2026

Many farmers, business owners, and homeowners use metal buildings because they offer several benefits, and cost-effectiveness is one of them. However, metal building prices are going to increase in 2026. It is happening due to many reasons that we have covered thoroughly here. If you plan to buy a steel building this year, now is the best time, as prices may increase later. For example, if the price of a steel barn building of size 48′-36′ starts at $6,325, it can increase after a few days or a month.

We have broken down the real reasons behind the price increase. You can explore them to understand why prices are rising in 2026.

What Do Metal Buildings Cost in 2026?

One of the most common questions buyers ask before moving forward is simple: how much does a metal building actually cost in 2026? While prices vary based on size, location, design, and features, most metal structures follow a predictable price range.

Here are some starting price estimates for different types of metal buildings in the USA. These prices can increase in the coming months.

Carport Prices:

- 40x24x14 All Vertical Metal Carport – $26,614

- 32x28x16 Steel Carport with Lap Siding – $22,280

- 30x65x12 Metal Utility Carport Building – $26,663

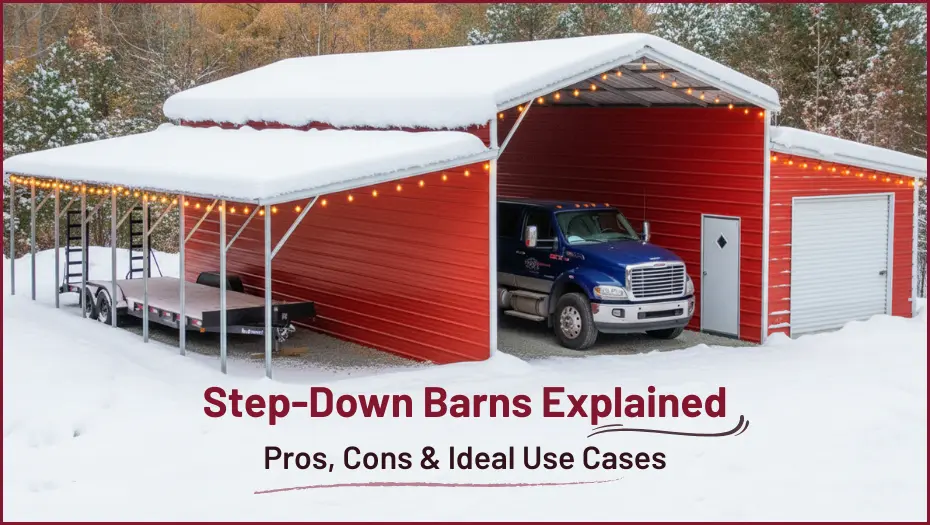

Barn Prices:

- 42x26x11 Raised Center Metal Barn – $10,115

- 44x40x14 Step Down Roof Barn – $26,585

- 60x61x16 Metal Lean To Barn – $60,138

Garage Prices:

- 60x24x14 All Vertical Building With Printed Walls – $69,140

- 50x52x14 Two Tone Metal Garage – $53,895

- 44x44x14 Three Car Metal Garage – $36,625

What Causes the Metal Building Price Increase in 2026?

There are many reasons behind the price increase. It is not going up due to a single reason. If you know these reasons increased cost of steel structures will not surprise you. And next time, you can plan ahead to buy before the raise.

1. Rising Steel Production Costs

Steel is the backbone of all metal buildings USA. When it becomes expensive, every type of structure, from steel barns to warehouses, automatically costs more.

- Raw Material Prices Are Increasing: Steel is made using iron ore, coal, limestone, and recycled scrap metal. In 2026, global demand for these raw materials is extremely high due to infrastructure projects, industrial expansion, defense and transportation needs, and many other reasons. At the same time, mining output and scrap availability have not grown at the same pace. This imbalance pushes raw material prices up. When steel mills pay more for inputs, those costs are passed on to steel building manufacturer and suppliers, and eventually to buyers. This is one of the biggest reasons why steel building prices are increasing significantly.

- Energy Costs Have a Direct Impact: Producing steel requires massive amounts of electricity, gas, and fuel. Steel mills operate heavy furnaces, cutting machines, and rolling systems that consume energy continuously. In 2026, energy prices in the USA remain unstable. Even small increases in electricity or fuel costs significantly raise production expenses. These higher operational costs are reflected in the final pricing of steel buildings in the USA.Well, energy costs are no longer temporary spikes. They are becoming a long-term reality, which means steel structure prices can stay elevated.

- Environmental Compliance Adds Extra Cost: Steel manufacturers must now comply with stricter environmental and emissions regulations. While this is good for sustainability, it also means: New equipment investments, Cleaner but slower processes, and Higher compliance costs. All these changes raise the base cost of structures like steel barns, sheds, carports, and many other spaces. Buyers may not see these details, but they are quietly added to the price of every custom steel building or standard prefabricated building.

2. Labor and Manufacturing Challenges

Even if prefabricated buildings are cost-effective in the long run, they would still cost more initially because of labor and production issues. Here is the detailed view of it.

- Shortage of Skilled Labor: Steel building manufacturing requires skilled professionals, including engineers, welders, fabricators, and quality inspectors. In 2026, many experienced workers have retired, and fewer young professionals are entering skilled trades. To attract and retain workers, manufacturers must offer higher wages, better benefits, and flexible schedules. These increased labor costs directly impact the pricing of small to commercial metal buildings.

- Manufacturing Delays and Backlogs: Demand for custom metal buildings USA has grown rapidly. Businesses want fast construction, farmers want durable barns, and industries want storage solutions. However, steel building manufacturer or suppliers have limits. When factories receive more orders than they can process quickly, they create backlogs. Longer production times increase overhead costs, which are again passed on to buyers. This is why quotes often change if you delay confirming your order.

- Customization Is More Expensive Than Before: A custom prefab structure is designed to meet specific size, load, and usage needs. In 2026, customization costs more because it requires extra engineering calculations, specialized components, and additional fabrication time. While customization adds value, it also adds cost. Even small design changes can noticeably increase the final price of a metal building.

3. Supply Chain and Transportation Costs

Steel buildings don’t just appear on-site; they move through a long supply chain. Their prefabricated parts are transported from the factory to the installation site.

- Transportation Costs Are Still High: Steel components are heavy and bulky. Transporting frames, panels, and roofing materials across states or regions requires specialized trucks and equipment. Fuel prices, driver shortages, and logistics constraints have made transportation expensive. These costs are included in quotes for metal buildings USA, especially for large projects.

- Dependence on Imported Components: Although many steel buildings are made in the USA, some components or raw materials are still imported. This is why trade regulations, tariffs, and international shipping delays can unexpectedly increase costs. Any disruption in imports affects pricing consistency for steel building dealers and then buyers.

- Storage and Inventory Expenses: When materials arrive early but cannot be delivered immediately, suppliers must store them. Storage, handling, and insurance costs add to the overall expense of a project. In 2026, these “hidden” costs are higher than before and reflected in the final pricing of prefab spaces.

4. Increased Demand Across Multiple Sectors

Another major reason prices are rising is simple. Nowadays, more people want steel buildings.

- Agricultural Expansion: Farmers prefer steel barn buildings because they are weather-resistant, low-maintenance, and long-lasting. And because of these features, many agribusinesses use hay barns to meet equipment storage needs, steel livestock shelters to support animal health, and grain and feed storage. But more demand puts pressure on supply.

- Commercial and Industrial Growth: Warehouses, distribution centers, workshops, and manufacturing units rely heavily on metal buildings. With e-commerce and logistics expanding, commercial demand has grown significantly for clear span mental buildings.

- Residential and Personal Use: More homeowners are now choosing custom steel garages, workshops, and storage units. This growing residential interest adds another layer of demand to the market. It also contributes to the rise in metal building costs.

How to Secure Space at the Current Price?

If you don’t want to pay higher costs for a metal structure, secure it now at current prices with a trusted steel building dealer. So, act wisely and follow the ways mentioned below.

1. Work with Reliable Metal Building Contractors:

First of all, search for top steel building dealers. It is because trusted building suppliers usually have better control over sourcing, logistics, and timelines. This reduces delays and surprise costs. Reliable companies also provide clearer contracts and more stable pricing.

2. Choose Prefabricated Buildings When Possible

Once you have found a dealer to buy a steel building, explore all the prefabricated buildings as per your needs. These structures typically require less engineering time and are produced faster, keeping costs lower than those of fully customized structures. If your project allows flexibility, this is one of the smartest cost-saving moves.

3. Avoid Unnecessary Custom Features

Extra height, complex roof styles, and decorative elements can quickly increase costs. Therefore, focus on function first. A practical design often delivers the same performance at a much lower price.

4. Lock in Your Price Early

Once you have decided on the structure, move to the next step- locking the price. Many metal building manufacturer or suppliers allow buyers to lock pricing once the design is finalized. This protects you from sudden steel price hikes during production. Delaying decisions often leads to higher quotes later.

Beat the 2026 Price Surge with a Trusted Partner

Metal building prices are rising in 2026, and this increase is driven by real, long-term factors. Steel production costs, labor shortages, energy prices, supply chain challenges, and growing demand are all pushing prices upward. Waiting may feel safe, but in reality, it often means paying more for the same steel building later. You can lock the price with the help of a reliable metal structure dealer, Viking Barns. They offer durable, well-engineered custom buildings, such as steel barns, garages, sheds, and carports with transparent pricing, dependable delivery, and trusted U.S. manufacturing standards.

Alabama AL

Alabama AL

American Steel Carports Inc.

American Steel Carports Inc.