Spray Foam Insulation Vs. Fiberglass: What’s Best For Your Metal Farm Building?

Your metal farm structure does a lot to protect animals, tools, machines, and crops. But without proper insulation, it can feel like a hot oven in summer and a freezing box in winter. Since metal structures heat up quickly, they need insulation to stay comfortable and energy-efficient.

But why insulate your metal farm building? It helps with –

- Temperature regulation

- Saves energy

- Condensation control

- Reduces noise

- Deter pests by sealing

In 2025, energy costs are up by 12% nationwide. That means keeping your building warm or cool is more expensive than ever. Good insulation helps you save money, control moisture, and protect your equipment from rust and damage.

This guide will help you compare spray foam and fiberglass insulation, the two popular choices for metal farm barns. We’ll compare how they work, what they cost, and how easy they are to install, so you can choose what’s best for your farm.

Level Up Your Knowledge – Read Out: Single Bubble vs. Double Bubble vs. Woven R-17 Insulation

What Are These Insulation Materials Made Of?

Spray Foam Insulation Material

It’s made using polyurethane chemicals that expand and harden into a foam. It is available in two types –

- Open Cell: Softer, Breathable, Lower R-value

- Closed Cell: Rigid, Moisture-Resistant, Higher R-value

Fiberglass Insulation Material

It is made from fine glass fibers spun into batts, rolls, or loose-fill. You can get it with a vapor barrier (in-faced) or without (unfaced).

It is made from fine glass fibers spun into batts, rolls, or loose-fill. You can get it with a vapor barrier (in-faced) or without (unfaced).

R-Value Comparison For Thermal Resistance

|

Type |

R-Value Per Inch |

Best Use Case |

|

Closed Cell Spray Foam |

5.5 |

|

|

Open Cell Spray Foam |

3.6 |

|

|

Fiberglass Batts |

3.1 to 4.3 |

|

| Loose Fill Fiberglass |

2.2 to 2.7 |

|

NOTE: These values help you estimate how thick your insulation needs to be to reach your desired energy efficiency.

Cost Breakdown For Spray Foam and Fiberglass Insulators

|

Insulation Type |

Material Cost (per sq. ft.) |

Installed Cost (per sq. ft.) |

|

Spray Foam (Closed Cell) |

$1.00 to $2.00 |

$3.95 to $7.20 |

|

Spray Foam (Open Cell) |

$0.45 to $0.80 |

$2.00 to $4.00 |

|

Fiberglass Batts |

$0.40 to $0.75 |

$1.65 to $3.40 |

|

Loose Fill Fiberglass |

$0.50 to $1.00 |

$2.00 to $3.50 |

| Note:

These are estimate costs and may fluctuate over time and with location. |

||

Installation Time and Skill Level Needed For Both

Installation of an insulator can be done faster by a professional than by DIYers, due to the use of specialized equipment and experience in both cases. However, skill needs can vary with the type of project and the size of the building.

- Spray Foam: It requires professional equipment and safety gear.

- Fiberglass Batts: It is DIY friendly and you can install it with basic tools.

- Loose-Fill Fiberglass: It needs a blower machine and is best done by professionals.

Pros and Cons Of Spray Foam and Fiberglass Insulation

Spray Foam Pros

First off, it offers an excellent air and moisture seal. It has the highest R-value per inch, hence, it is best to maintain temperature of metal barns in summer and during cold winters. It also has a long lifespan of up to 80+ years and can reduce your utility bills and save some money.

Spray Foam Cons

One of the disadvantages of spray foam insulator is that it has a high upfront cost and requires a professional installation team. Plus, it is made using petroleum-based chemicals and can’t be recycled once installed.

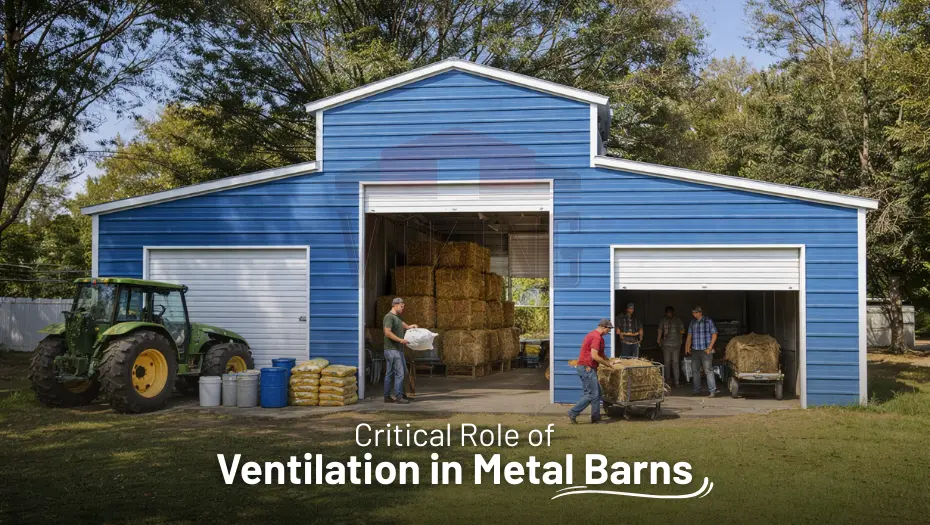

Further, it may release harmful VOCs during and after installation, and your steel custom barn must be well ventilated during the process (about 24 to 72 hours). It may lead to poor air quality if the ventilation is poor.

Fiberglass Pros

It is affordable and widely available in the country. You can easily install it (especially batts), and these are made using eco-friendly (recycled glass) materials. These fire-resistant and non-toxic insulators can stand strong against cold in a metal barn when installed correctly. You can use it in walls, attics, ceilings, crawl spaces, and between studs and joists in a prefab barn structure.

Fiberglass Cons

It is low in R-value and can lose effectiveness if wet. If not done properly, it can irritate skin, eyes, and lungs during installation.

Safety and Health Considerations For These Insulators

Spray Foam: It emits VOCs (volatile organic compounds) during application, so ensure to wear a respirator and protective gear. If removed, it may release toxic dust and can be an environmental concern. Choosing the right insulation, you can save more on steel buildings overall.

Fiberglass: It can release airborne particles, so wear gloves, goggles, and a mask during application (esp. if you are DIYing). It can develop mold risk if fiberglass gets wet and stays damp. It is easier to replace and upgrade over time.

Spray Foam and Fiberglass Insulator Performance Under Different Climates

|

Climate Zone |

Recommended Insulation |

|

Humid southeast |

Closed cell spray foam |

|

Dry southwest |

Fiberglass batts |

| Cold Midwest/ northeast |

Spray foam (for air sealing) |

| Mixed-use farms |

Combo: spray foam + fiberglass |

Use Cases Of Insulator For Steel Agriculture Buildings

A steel agriculture building can be used in lots of ways, and choosing the right insulation depends on what you are using the prefabfor, such as –

| Livestock Shelters: | Spray foam for moisture control, to keep animals warm in winters, and for sealing drafts and pests |

| Equipment Storage: | Fiberglass for budget-friendly insulation for large spaces and to keep machines and tools safe from temperature fluctuations |

| Workshops: | Spray foam for soundproofing and temperature control |

| Greenhouses: | Open-cell foam because it allows moisture and air to pass through and maintains a healthy indoor for plants |

What Insulation Should You Choose For Your Farm Metal Building?

So, which insulation option should you pick – spray foam or fiberglass? Let’s see –

Go With Spray Form If:

- You want a top-notch energy-efficient system to keep your building warm in winter and cool in summer.

- Your farm is in a place with humid weather, heavy rain, and extreme temperatures.

- You can spend more money upfront for long-term savings.

- You need strong air sealing to block drafts and moisture for the animals’ comfort.

- You want a metal farm building to feel sturdy and sealed with extra structural support.

- You want to use the barn space more often for things that demand a stable temperature.

Spray foam is a type of steel farm building insulation that will give your building a warm, protective hug that lasts for years.

Want a Deeper Dive? Check Out Our Full Guide On: Comprehensive Guide To Steel Farm Building Insulation Options

Go With Fiberglass If:

- You are on a tight budget and want an affordable option for farm building.

- Your prefab barn structure is in a dry, mild climate where moisture is not a big issue.

- You like DIY projects, and you are confident about installing batts yourself.

- The structure is meant for the storage of items that are less sensitive and don’t need perfect temperature control.

- You are willing to add a separate vapor barrier to help block moisture.

One of the best tips to maintain a steel barn is to have solid insulation without spending too much and making sure to check it annually for addressing any repairs or minor fixes.

Moisture, Heat, Budget? Find Your Best Fit Now!

Both spray foam and fiberglass insulation have their strengths, such as the former seals air leaks but costs more and needs a professional to install, while the latter is affordable and easy DIY but does not seal as tightly and may not last long in tough farm conditions.

So, which one should you choose? You need to think about –

- Your climate (cold winters or hot summers)

- Your budget (save now or invest in the long run)

- Building’s use (livestock, storage, or workspace?)

- DIY or pro help

By weighing these factors, you can pick between the two that keeps your steel farm building comfortable, efficient, and safe for years to come.

Alabama AL

Alabama AL

American Steel Carports Inc.

American Steel Carports Inc.